Demystifying Construction Progress Using Forensic Schedule Analysis

Odds are, if you have embarked on a construction project of any shape or size, you have heard the dreaded words, “There’s been a delay in the schedule.” Building in today’s climate has become almost synonymous with delays. Maybe your contractor insists that everything is on track, but you are observing consistent slippage in critical activities over time. The reality of construction in the K-12 industry is there is no time for hidden delays or surprises—the school calendar demands accuracy and completion with little room for schedule adjustments. If your instinct is telling you progress is behind, but you can’t quite prove it, HPM has the solution for you.

Half-Step Period Analysis

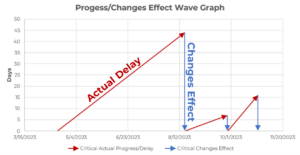

Half-Step Period Analysis can help reveal what is going on under the surface of a construction schedule. This method stores schedule updates and quantifies the impact, whether good or bad, of field progress on a schedule at large. Conveniently for the user, this approach collects the progress information from a new update to the schedule and applies only that piece of information to the prior schedule. The schedule is then recalculated and the impact on progress can be observed and analyzed. At this point, you will find answers to your most pressing questions: Did the end date move? Did the critical path change? How will our plans be impacted? Once this data is calculated, it can easily be mapped out in a visual format for further analysis.

What Next?

Now that we have proof that slippage has occurred, we can begin studying the updated critical path. Reviewing the schedule changes provides insight into how the lost time will be recovered. Studying these adjustments spelled out on paper enables you to see if the changes are reasonable. Armed with this information, you are then prepared to discuss a plan of action with the contractor that will allow the project to truly remain on track.

Is This a Recognized Method of Schedule Analysis?

A recent project utilized this method to encourage schedule transparency with a contractor. This case used modularized construction, an approach in which main portions of the facility were fabricated like building blocks. This method demands that stages of progress build upon one another in order to move on to the next phase. In this instance, production of these “blocks” slipped behind by four months with significant delays to production. In spite of an obvious delay, the contractor maintained the position that the project was on track to reach its original completion date.

By applying half-step period analysis, data came together to prove gaps in the unaffected schedule the contractor was promising. Identifying these issues early in the project allowed for impactful remediation plans to be implemented, as well as identifying staffing needs well in advance of their respective start dates. This knowledge on the front end proved critical in today’s market where manpower can be difficult to acquire.

The Power of Period Analysis

When implemented early on in construction, period analysis can detect impacts to schedule before they occur. This data provides actionable information and a path forward. Using this knowledge, project teams can implement recovery plans and avoid critical delays.